法蘭排渣閘閥-法蘭排渣閘閥廠(chǎng)家–富力都閥門(mén)

| 型號(hào) | 公稱(chēng)壓力 (MPa) | 實(shí)驗(yàn)壓力 | 工作溫度(℃) | 適用介質(zhì) | ||

| 強(qiáng)度(水)(Mpa) | 密封(水)空氣 | 低壓密封空氣(Mpa) | ||||

| Z4IH-16C Z41W-16P(R) | 1.6 | 2.4 | 1.8 | 0.6 | ≤200 | NITRICACID |

| 硝酸類(lèi) | ||||||

| ACETICACID | ||||||

| 醋酸類(lèi) | ||||||

| NITRICACID | ||||||

| Z41W-25P(R) | 2.5 | 3.8 | 2.8 | 0.6 | ≤200 | 硝酸類(lèi) |

| Z41W-40P(R) | 4.0 | 6.0 | 4.4 | 0.6 | ≤200 | ACETICACID |

| Z41W-64P(R) | 6.4 | 9.6 | 7.0 | 0.6 | ≤200 | 醋酸類(lèi) |

| 閥體/閥蓋 | ZG1Cr18Ni9Ti | ZG00Cr18Ni10 | ZG1Cr18Ni12Mo2Ti | ZG00Cr17Ni14Mo2 | WCB |

| 零件名稱(chēng) | ZG1Cr18Ni9Ti系列 | ZG00Cr18Ni10系列 | ZG1Cr18Ni12Mo2Ti系列 | ZG00Cr17Ni14Mo2系列 | WCB系列 |

| 閘板 | ZG1Cr18NI9Ti | ZG00Cr18Ni10 | ZG1Cr18Ni12Mo2Ti | ZG00Cr17Ni14Mo2 | 1Cr13 |

| 閥桿 | 1Cr18Ni9Ti | ooCr18Ni10 | 1Cr18Ni12Mo2Ti | ooCr17Ni14Mo2 | 1Cr13 |

| 填料 | PTFE編織 | PTFE編織 | PTFE編織 | PTFE編織 | 石墨Graphite |

| 墊片 | 304L+PTFE | 304L+PTFE | 316L+PTFE | 316L+PTFE | 石墨+304 Graphite+304 |

| 壓蓋 | ZG1Cr181Ni10 | ZG00Cr18Ni10 | ZG1Cr18Ni12Mo2Ti | ZG00Cr17Ni14Mo2 | WCB |

| 填料壓環(huán) | 1Cr18Ni9Ti | 00Cr18Ni10 | 1Cr18Mi12Mo2Ti | 00Cr17Ni14Mo2 | 1Cr13 |

| 螺栓 | 1Cr171Ni2 | 1Cr171Ni2 | 1Cr171Ni2 | 1Cr171Ni2 | 35CrMoA |

| 螺母 | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 1Cr18Ni9Ti | 45 |

| 型號(hào) | 公稱(chēng)壓力 (MPa) | 實(shí)驗(yàn)壓力 | 工作溫度(℃) | 適用介質(zhì) | ||

| 強(qiáng)度水(MPa) | 密封(水)空氣(MPa) | 低壓密封空氣(MPa) | ||||

| Z41W-16P(R) | 1.6 | 2.4 | 1.8 | 0.6 | ≤200 | 硝酸類(lèi) |

| Z41W-25P(R) | 2.5 | 3.8 | 2.8 | 0.6 | ≤200 | 醋酸類(lèi) |

| Z41W-40P(R) | 4.0 | 6.0 | 4.4 | 0.6 | ≤200 | 硝酸類(lèi) |

| Z41W-64P(R) | 6.4 | 9.6 | 7.0 | 0.6 | ≤200 | 醋酸類(lèi) |

| 尺寸 | DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| L | mm | 130 | 150 | 160 | 180 | 200 | 250 | 265 | 280 | 300 | 325 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 800 |

| H | mm | 175 | 180 | 210 | 210 | 350 | 358 | 373 | 435 | 500 | 614 | 674 | 818 | 1225 | 1415 | 1630 | 1780 | 2050 | 2181 | 2599 |

| W | mm | 180 | 180 | 200 | 200 | 200 | 240 | 240 | 280 | 320 | 360 | 360 | 400 | 450 | 500 | 500 | 600 | 720 | 720 | 720 |

| 尺寸 | DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 |

| L | mm | 130 | 150 | 160 | 180 | 200 | 250 | 265 | 280 | 300 | 325 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 800 |

| H | mm | 175 | 180 | 210 | 210 | 350 | 358 | 373 | 435 | 500 | 614 | 674 | 818 | 1225 | 1415 | 1630 | 1780 | 2050 | 2181 | 2599 |

| W | mm | 180 | 180 | 200 | 200 | 200 | 240 | 240 | 280 | 320 | 360 | 360 | 400 | 450 | 500 | 500 | 600 | 720 | 720 | 720 |

| 尺寸 | DN | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 | 250 | 300 | 350 | 400 |

| L | mm | 130 | 150 | 160 | 180 | 200 | 250 | 280 | 310 | 350 | 400 | 450 | 550 | 650 | 750 | 850 | 950 |

| H | mm | 175 | 180 | 210 | 210 | 350 | 358 | 373 | 435 | 500 | 614 | 674 | 818 | 1225 | 1415 | 1630 | 1780 |

| W | mm | 180 | 180 | 200 | 200 | 200 | 240 | 240 | 280 | 320 | 360 | 360 | 400 | 450 | 500 | 500 | 600 |

LOHSELOHSE刀閘閥

武田機(jī)電

![]()

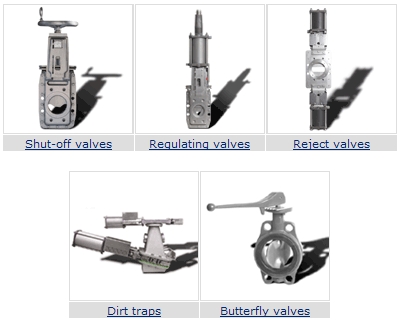

LOHSE閥門(mén),LOHSE刀閘閥,LOHSE截止閥,LOHSE調(diào)節(jié)閥,LOHSE排渣閥,LOHSE蝶閥

德國(guó)LOHSE成立于1962,其生產(chǎn)的刀閘閥廣泛地應(yīng)用于造紙及化工行業(yè).產(chǎn)品已通過(guò)ISO 9001認(rèn)證.

valves CNA Shut-off valves CDS Shut-off valves CAW Shut-off valves CDSV

MARTIN LOHSE GmbH Over 40 years' experience and success in valve construction LOHSE Knife Gate Valves for the Paper and Chemical Industry Long before the actual start of our valve development and production programme in 1962, we were already partners of the paper industry. As manufacturers of pulp vats, containers and machine parts our specialists were always present when it was a matter of solving problems at our customers. It was therefore a logical step that we also addressed the problems of valve technology handling pulp and fibre. The complete development of our knife gate valves rests always on close coordination with the experts from paper and paper machine manufacturers.

LOHSE閥門(mén)開(kāi)發(fā)與生產(chǎn)計(jì)劃在1962年的實(shí)際開(kāi)始,LOHSE已經(jīng)造紙行業(yè)的合作伙伴。作為紙漿大桶,容器及機(jī)械零件制造商的專(zhuān)家總是在場(chǎng),這是一個(gè)在我們的客戶(hù)解決問(wèn)題的問(wèn)題。因此,一個(gè)合乎邏輯的步驟,我們也解決了閥門(mén)的技術(shù)問(wèn)題的處理紙漿和纖維。 LOHSE刀閘閥發(fā)展在于總是在與從紙張和造紙機(jī)制造商的專(zhuān)家密切協(xié)調(diào)。這種演變開(kāi)始與鑄鐵閥和帶內(nèi)襯不銹鋼通過(guò)與腐蝕,耐酸不銹鋼制成。

This evolution began with valves made of cast iron and continued with valves lined with stainless through to today with valves made of corrosion and acid resistant stainless steel. The reject valves that were developed parallel to this and were conceived for the problem positions in waste paper processing, have since become the standard in recycling paper mills. We are now the only renowned manufacturer of knife gate valves with a service-friendly two-part housing. All others have long since abandoned this design because of manufacturing costs and now only have valve bodies with a one part housing. But the simplest way of replacing wearing parts is if the housing is in two parts. In addition, the one-part housing has the following further disadvantage: the space for inserting the valve plate in the housing has to be relatively large and this increases the danger of blocking and draining paper fibres. With our valve, this problem is prevented by the narrow tolerances between the valve plate and the smooth-running plastic internal shell. The valve guides are emptied via a specially shaped sturdy valve plate. A sophisticated system for attaching accessories and the drives - which are found here as the LOHSE modular system - is another advantage of our concept. Our repair service restores your used LOHSE COMPACT valve to an as-new condition with the guarantee of a new valve. What our customers appreciate in us: detailed advice on site on valve type and installation situation preparation of a customised offer fastest delivery times thanks to independence from sub-contractors simplest build-on possibilities for all technical accessories such as limit switches, positioners, terminal boxes, etc. competent training for the installation and maintenance personnel on site or on our premises quality guarantee through own production - the product is “Made in Germany” CE 0036 / ISO 9001 simplest replacement of wearing parts through service-friendly two-part housing our own repairs department guarantees repairs with full factory guarantee day-to-day personal support for our customers through our service technicians maintenance contracts provide the best possible security further development of our products in close cooperation with our partners in the paper industry

LOHSE閥門(mén),LOHSE刀閘閥,LOHSE截止閥,LOHSE調(diào)節(jié)閥,LOHSE排渣閥,LOHSE蝶閥

楔式法蘭閘閥

產(chǎn)品名稱(chēng):楔式法蘭閘閥

產(chǎn)品型號(hào):Z41H(W)(Y)

壓力等級(jí):1.6Mpa~16Mpa

產(chǎn)品規(guī)格:DN25.~1000mm

產(chǎn)品材質(zhì):碳鋼、不銹鋼

適用溫度:≤425 oC

適用介質(zhì):水、蒸氣、油品、酸、堿類(lèi)

公稱(chēng)通徑:DN15至400;法蘭柱塞閥 柱塞截止閥 柱塞閘閥

性能:

公稱(chēng)壓力:PN1.6、2.5、4.0、6.4MPa;

公稱(chēng)通徑:DN15至400;

閥體材質(zhì):鑄鐵、鑄鋼、碳鋼WCB、不銹鋼304、316;

法蘭連接;

溫度:≤250℃、≤300℃。

相關(guān)柱塞閥產(chǎn)品:

法蘭柱塞閥 柱塞截止閥 柱塞閘閥 鑄鐵柱塞閥 鑄鋼柱塞閥 絲口柱塞閥 雙向二通柱塞閥 硬密封柱塞閥 蒸汽柱塞閥

閘閥 不銹鋼閘閥 美標(biāo)閘閥 磅級(jí)閘閥 鑄鋼閘閥 平板閘閥

閘閥的啟閉件是閘板,閘板的運(yùn)動(dòng)方向與流體方向相垂直,閘閥只能作全開(kāi)和全關(guān),不適合作調(diào)節(jié)和節(jié)流。閘板有兩個(gè)密封面,最常用的楔式閘板閥的兩個(gè)密封面形成楔形,楔形角隨閥門(mén)參數(shù)而異,通常為5o。楔式閘閥的閘板可以做成一個(gè)整體,叫做剛性閘板;也可以做成能產(chǎn)生微量變形的閘板,以改善其工藝性,彌補(bǔ)密封面角度在加工過(guò)程中產(chǎn)生的偏差,這種閘板叫做彈性閘板。閘閥關(guān)閉時(shí),密封面可以只依靠介質(zhì)壓力來(lái)密封,即依靠介質(zhì)壓力將閘板的密封面壓向另一側(cè)的閥座來(lái)密封面的密封,這就是自密封。大部分閘閥是采用強(qiáng)制密封的,即閥門(mén)關(guān)閉時(shí),要依靠外力強(qiáng)行將閘板壓向閥座,以密封面的密封性。閘閥具有以下優(yōu)點(diǎn); 1.流體阻力小,密封面受介質(zhì)的沖刷和侵蝕小。 2.開(kāi)閉較省力。 3.介質(zhì)流向不受限制,不擾流、不降低壓力。 4.形體簡(jiǎn)單,結(jié)構(gòu)長(zhǎng)度短,制造工藝性好,適用范圍廣。公稱(chēng)壓力或壓力級(jí):PN1.0-16.0MPa、ANSI CLASS 150-300LB、JIS10-20K 公稱(chēng)通徑或口徑:DN10~1000、NPS 1/2 ~36" 連接方式:法蘭、對(duì)焊、螺紋等適用溫度:-196℃~700℃驅(qū)動(dòng)方式:手動(dòng)、傘齒輪傳動(dòng)、氣動(dòng)、電動(dòng)、液動(dòng)、氣液聯(lián)動(dòng)、電液聯(lián)動(dòng)

PZ43手動(dòng)刀型閘閥

PZ43手動(dòng)刀型閘閥 上海華鋼閥業(yè)

設(shè)計(jì)緊湊、占據(jù)空間小、重量輕、易于安裝、耐磨防堵措施完善,便于維修,使用壽命長(zhǎng)。廣泛應(yīng)用于食品飲料、造紙、紙漿工業(yè)、工業(yè)污水、城市污水處理、化工廠(chǎng)、散狀物料輸送、飛灰處理行業(yè)。

RVC(E)X彈性座封閘閥

RVC(E)X彈性座封閘閥

以來(lái)市場(chǎng)上使用的一般閘閥普遍存在著漏水或生銹現(xiàn)象,本企業(yè)引進(jìn)歐洲高科技橡膠及閥門(mén)制造技術(shù)所生產(chǎn)的彈性座封閘閥,克服了一般閘閥密封不良,生銹等缺陷,彈性座封閘閥利用彈性閘板產(chǎn)生微量彈性變形的補(bǔ)償作用達(dá)到良好的密封效果,該閥具有開(kāi)關(guān)輕巧、密封、彈性記憶佳及使用壽命等顯著優(yōu)點(diǎn)。可廣泛用于自來(lái)水、污水、建筑、石油、化工、食品、醫(yī)藥、輕紡、電力、船舶、冶金、能源系統(tǒng)等體管線(xiàn)上作為調(diào)節(jié)和截流裝置使用。

PZ973H、PZ973F、PZ973Y上海滬工閥門(mén)福州電動(dòng)刀閘閥銷(xiāo)售

| DN | L | D | D1 | D2 | H | z×M | D0 |

|---|---|---|---|---|---|---|---|

| 50 | 43 | 160 | 125 | 99 | 285 | 4×M16 | 180 |

| 65 | 46 | 185 | 145 | 120 | 295 | 4×M16 | 180 |

| 80 | 46 | 200 | 160 | 135 | 315 | 8×M16 | 220 |

| 100 | 52 | 220 | 180 | 155 | 365 | 8×M16 | 220 |

| 125 | 56 | 250 | 210 | 185 | 400 | 8×M16 | 230 |

| 150 | 56 | 285 | 240 | 210 | 475 | 8×M20 | 280 |

| 200 | 60 | 340 | 295 | 265 | 540 | 12×M20 | 360 |

| 250 | 68 | 405 | 355 | 310 | 630 | 12×M22 | 360 |

| 300 | 78 | 460 | 410 | 375 | 780 | 12×M22 | 400 |

| 350 | 78 | 520 | 470 | 435 | 885 | 16×M22 | 400 |

| 400 | 102 | 580 | 525 | 485 | 990 | 16×M27 | 400 |

| 450 | 114 | 640 | 585 | 545 | 1100 | 20×M27 | 530 |

| 500 | 127 | 715 | 650 | 609 | 1200 | 20×M30 | 530 |

| 600 | 154 | 840 | 770 | 720 | 1450 | 20×M36 | 600 |

| 800 | 190 | 1025 | 950 | 898 | 2000 | 24×M36 | 680 |

訂貨流程

訂貨流程1. 客戶(hù)采購(gòu)清單請(qǐng)來(lái)電至 ,或來(lái)電咨詢(xún)15802023078。

2. 收到客戶(hù)采購(gòu)清單,為客戶(hù)提供閥門(mén)型號(hào)選型與報(bào)價(jià)(價(jià)格清單)。

3. 具體商定:交貨期、特殊要求等事宜。

訂貨須知1. 客戶(hù)對(duì)產(chǎn)品有特殊要求,須在訂貨合同中提供以下說(shuō)明:

1. 結(jié)構(gòu)長(zhǎng)度

2. 連接形式

3. 公稱(chēng)直徑、全通徑、縮徑、管道尺寸

4. 運(yùn)用介質(zhì)及溫度、壓力范圍

5. 實(shí)驗(yàn)、檢驗(yàn)標(biāo)準(zhǔn)及其他要求

2. 本場(chǎng)可根據(jù)客戶(hù)特殊要求配置各類(lèi)驅(qū)動(dòng)裝置。

3. 如由客戶(hù)提供確定的閥門(mén)類(lèi)型和型號(hào)時(shí),客戶(hù)應(yīng)正確說(shuō)明其型號(hào)的含義和要求,在供需雙方理解一致的條件下簽訂合同。

RVHX/Z45XRVHX/Z45X暗桿軟密封閘閥

暗桿軟密封閘閥特點(diǎn):

傳統(tǒng)的閘閥往往在通水洗管后即因外物諸如石頭,木塊,水泥,紙屑,雜物等淤積于閥底凹槽內(nèi)。容易造成無(wú)法關(guān)閉緊密而形成漏水現(xiàn)象,暗桿彈性座封閘閥(RVHX/Z45X-16)低部采用與水管相同的平底設(shè)計(jì),不易造成雜物淤積,使流體通暢無(wú)阻。·整體包膠 閥板采用高品質(zhì)的橡膠進(jìn)行整體內(nèi),外包膠,國(guó)內(nèi)一流的橡膠硫化技術(shù)使得硫化后的閥板能夠保證精確的幾何尺寸,且橡膠與球墨鑄鐵閘板連接牢靠,不易脫落及彈性記憶佳。 ·耐腐蝕 閥閥體采用粉沫環(huán)氧樹(shù)脂涂裝,可防止閥體的腐蝕與生銹,并可用于污水系統(tǒng)。 ·不易碎裂 以往傳統(tǒng)鑄鐵閘閥常園外物擊中,碰撞或重疊而造成斷裂等現(xiàn)象。由于本閥改用球墨鑄鐵,此種情形已可大幅度減少。 ·三“O”型環(huán)密封圈 由于閥桿采用三“0”型環(huán)密封圈密封設(shè)計(jì),可減少開(kāi)關(guān)時(shí)的磨擦阻力,大幅減少漏水現(xiàn)象殛可以不停水施工更換密封圈。 ·有助生飲 由于閥體內(nèi)部以無(wú)毒性環(huán)氧樹(shù)脂涂裝,閘板的內(nèi)外表面均以橡膠完全包覆而不至于出現(xiàn)銹水或腐蝕現(xiàn)象,可供生飲。·精鑄閥體 閥體采用精密鑄造,精確的幾何尺寸使得閥體內(nèi)部無(wú)需任何精加工即可保證閥門(mén)的密封性。 ·重量輕 本閥采用球墨鑄造而成,重量較傳統(tǒng)閘閥重量減輕約20%-30%。安裝維修方便。暗桿軟密封閘閥設(shè)計(jì)標(biāo)準(zhǔn):

平底設(shè)計(jì) 閥底無(wú)凹槽,不易沉積焊渣、石子、泥沙等雜物,確保密封可靠,流體暢通;

整體包膠: 閘板采用優(yōu)質(zhì)橡膠進(jìn)行整體內(nèi)外包膠,硫化后的閘板能夠保證精確的幾何尺 寸,配合以精密鑄造的閥體,形成天衣無(wú)縫的密封副,確保閥門(mén)的零泄漏。且橡膠與球墨鑄鐵閘板膠合牢靠,彈性記憶性好;

精鑄殼體: 閥體采用精密鑄造,精確的幾何尺寸使得閥體內(nèi)部無(wú)需任何加工,閘板和閥體實(shí)現(xiàn)通配,方便維修和更換;

耐腐涂裝: 閥體內(nèi)外表面與介質(zhì)接觸的部位采用環(huán)氧樹(shù)脂涂裝,閥桿采用不銹鋼材質(zhì),閥桿螺母采用銅合金材質(zhì),閘板全面包覆小腳過(guò)年避免產(chǎn)生銹蝕,可用于純凈水系統(tǒng)、污水系統(tǒng)及地下惡劣環(huán)境;

在線(xiàn)維修: 閥體與閥桿連接采用三道“O”形環(huán)密封,減少啟閉扭矩,大幅度減少漏水現(xiàn)象,并可以在線(xiàn)更換密封圈。

暗桿軟密封閘閥主要參數(shù):

| 壓力等級(jí) | 1.0MPa、1.6MPa、2.5MPa |

| 閥體耐壓 | 1.5MPa、2.4MPa、3.75MPa |

| 密封試驗(yàn) | 1.1MPa、1.76MPa、2.75MPa |

| 工作溫度 | 0~80℃ |

| 適用介質(zhì) | 水、油、蒸氣等 |

VTON進(jìn)口不銹鋼閘閥|世界品牌不銹鋼法蘭閘閥|304閘閥|316閘閥

進(jìn)口不銹鋼閘閥|世界品牌不銹鋼法蘭閘閥|304閘閥|316閘閥

概述

閘閥是指關(guān)閉件(閘板)沿通路中心線(xiàn)的垂直方向移動(dòng)的閥門(mén),當(dāng)介質(zhì)流體對(duì)閥體材質(zhì)要求較高時(shí),比如腐蝕,酸堿介質(zhì),必須選用進(jìn)口不銹鋼閘閥,(Stainless steel gate valve)它是指采用不銹鋼(304、316、316L)作為閥體材質(zhì)的閘閥,閥門(mén)任性更好,耐溫更高,耐壓更強(qiáng),而且耐腐蝕;

Gate valve is a valve down part (disc) is moved along the vertical direction of the channel centerline when the the Fluid Body material requirements, such as corrosion, acid and alkali media, you must use the imported stainless steel gate valve, which is made of stainless steel(304,316,316 L) as the body material of the valve, the valve wayward better, higher temperature, pressure stronger, and corrosion-resistant

美國(guó)威盾進(jìn)口不銹鋼閘閥有以下特征:

1、不銹鋼閘閥流體阻力小, 密封面受介質(zhì)的忡刷和侵蝕小。

2、不銹鋼閘閥開(kāi)閉較省力。

3、不銹鋼閘閥介質(zhì)流向不受限制 , 不擾流、不降低壓力。

4、不銹鋼閘閥形體簡(jiǎn)單 , 結(jié)構(gòu)長(zhǎng)度短,制造工藝性好,適用范圍廣。

不銹鋼閘閥適用于公稱(chēng)壓力PN1.6~16.0MPa,工作溫度-29℃~550℃的石油、化工、水力、火力電站各種系統(tǒng)的管路上,切斷或接通管路介質(zhì)。適用介質(zhì)為:硝酸類(lèi)、醋酸類(lèi)、水、油、氣類(lèi)及某些腐蝕性液體。

如果您有需要咨詢(xún)更詳細(xì)產(chǎn)品價(jià)格、型號(hào)、產(chǎn)品的尺寸和技術(shù)資料

請(qǐng)咨詢(xún)授權(quán)代理商--深圳歐閥進(jìn)出口貿(mào)易有限公司

聯(lián)系人:張先生

電話(huà):

手機(jī):13428666198 http://www.fm5899.com

進(jìn)口閥門(mén):http://www.588fm.com http://www.588fm.com/sitemap.htm

最新產(chǎn)品

- 日本ANRITSU安立手持式溫度計(jì)主機(jī) 2025/4/17 1:27:07

- 日本ANRITSU安立手持式溫度計(jì)主機(jī) 2025/4/17 1:26:30

- 日本ANRITSU安立手持式溫度計(jì)主機(jī) 2025/4/17 1:23:37

- 日本ANRITSU安立手持式溫度計(jì)主機(jī) 2025/4/17 1:22:56

- 日本ANRITSU安立手持式溫度計(jì)主機(jī) 2025/4/17 1:20:41

- 日本ANRITSU安立手持式溫度計(jì)主機(jī) 2025/4/17 1:19:20

- 日本ANRITSU安立手持式溫度計(jì)主機(jī) 2025/4/17 1:16:27

- 日本ANRITSU安立手持式溫度計(jì)主機(jī) 2025/4/17 1:15:37

- 日本ANRITSU安立手持式溫度計(jì)主機(jī) 2025/4/17 1:10:29

- 日本ANRITSU安立手持式溫度計(jì)主機(jī) 2025/4/17 1:09:15

- 日本ANRITSU安立HR系列手持式溫度計(jì)主機(jī) 2025/4/17 1:06:44

- 日本ANRITSU安立HR系列手持式溫度計(jì)主機(jī) 2025/4/17 1:06:03

- 日本ANRITSU安立HR系列手持式溫度計(jì)主機(jī) 2025/4/17 1:01:52

- 日本ANRITSU安立HR系列手持式溫度計(jì)主機(jī) 2025/4/17 1:01:03

- 日本ANRITSU安立HR系列手持式溫度計(jì)主機(jī) 2025/4/17 0:58:28

- 日本ANRITSU安立HR系列手持式溫度計(jì)主機(jī) 2025/4/17 0:56:34

- 日本安立ANRITSU貼片型溫度傳感器 2025/4/17 0:45:54

- 日本安立ANRITSU貼片型溫度傳感器 2025/4/17 0:45:08

- 日本安立ANRITSU貼片型溫度傳感器 2025/4/17 0:44:27

- 日本安立ANRITSU貼片型溫度傳感器 2025/4/17 0:43:29

- 日本安立ANRITSU貼片型溫度傳感器 2025/4/17 0:41:28

- 日本安立ANRITSU貼片型溫度傳感器 2025/4/17 0:40:49

- 日本安立ANRITSU貼片型溫度傳感器 2025/4/17 0:38:38

- 日本安立ANRITSU貼片型溫度傳感器 2025/4/17 0:37:56

- 日本安立ANRITSU貼片型溫度傳感器 2025/4/17 0:36:34

- 日本安立ANRITSU貼片型溫度傳感器 2025/4/17 0:35:58

- 日本安立ANRITSU貼片型溫度傳感器 2025/4/17 0:35:17

- 日本安立ANRITSU貼片型溫度傳感器 2025/4/17 0:34:12

- 日本安立隙間插入型溫度傳感器 2025/4/16 23:01:56

- 日本安立隙間插入型溫度傳感器 2025/4/16 23:01:21